What Are Telecommunication Cables and What Are They Used For?

Telecommunication cables are specially designed communication lines used to transmit voice, data, and video signals. These cables are widely used in the communication industry and are optimized for different types of data transmission.

Types of Cables

Telecommunication cables come in various types:

- Fiber Optic Cables: Fiber optic cables, which use light, provide high-speed data transmission. Fiber optic cables are ideal for communication over long distances and high bandwidth.

- Copper Cables: Copper cables are used for transmitting electrical signals. Copper cables like Ethernet cables are commonly used for computer networks and internet connections.

What Are They Used For?

Telecommunication cables are essential components of modern communication infrastructure and serve a variety of important functions:

- Data Transmission: Telecommunication cables enable the reliable transmission of various types of information such as voice, video, and data. These cables form the backbone of internet, telephone, television, and other communication services.

- Long-Distance Connectivity: Fiber optic cables provide high-speed data transmission over long distances, enabling connectivity between distant locations worldwide and facilitating global communication.

- High Bandwidth: Fiber optic cables enable communication with high bandwidths, allowing for the rapid transmission and processing of large amounts of data, thereby increasing internet speed and bandwidth.

- Reliability: Telecommunication cables provide reliable and continuous communication. Fiber optic cables, in particular, are resistant to electrical interference, making them highly reliable.

Telecommunication cables are an indispensable part of modern communication infrastructure. They are used to reliably transmit voice, data, and video signals and play a critical role in providing internet, telephone, television, and other communication services. Our company aims to meet our customers' communication needs by offering high-quality telecommunication cables.

Technical Specifications of Telecommunication Cables

Telecommunication cables are specially designed communication lines used to transmit voice, data, and video signals reliably. These cables have a number of technical specifications:

Fiber Optic Cables

- Core Material: Fiber optic cables' core material is typically made of glass or plastic. Glass fiber optic cables provide communication over longer distances, while plastic fiber optic cables are more cost-effective.

- Bandwidth: Fiber optic cables provide communication with high bandwidths, enabling the rapid transmission of large amounts of data.

- Application: Fiber optic cables are ideal for long-distance, high-speed data transmission. They are used in various communication services such as internet, telephone, and television.

Copper Cables

-

- Cable Thickness: The thickness of copper cables affects their transmission capacity. Thicker copper cables allow for higher data transmission speeds.

- Insulation Material: The outer insulation of copper cables is usually made of plastic or rubber, enhancing the cables' resistance to external influences.

- Application: Copper cables are commonly used in short-distance communication applications such as computer networks and internet connections.

Waterproofing and Durability

-

- Outer Coating: Telecommunication cables are often coated with waterproof outer coatings, enhancing their resistance to external influences and ensuring reliable communication in outdoor conditions.

Electrical Performance

- Signal Strength: The signal strength of telecommunication cables affects transmission speed and data transmission capacity. High-quality cables provide low signal loss, ensuring stronger transmission performance.

The technical specifications of telecommunication cables are critical for the reliability and performance of communication infrastructure. While fiber optic cables' high bandwidth and long-distance transmission capabilities form the basis of modern communication systems, copper cables are widely used in short-distance communication applications. Our company aims to meet our customers' communication needs by offering telecommunication cables tailored to their requirements.

Applications of Telecommunication Cables

Telecommunication cables are specially designed communication lines used in a wide range of applications in the communication industry. These cables are commonly used in the following areas:

-

Internet Infrastructure

Telecommunication cables form the backbone of internet infrastructure. Fiber optic cables enable high-speed data transmission, providing broadband internet access.

-

Telephone Lines

Traditional telephone lines and Voice over Internet Protocol (VoIP) systems transmit voice over telecommunication cables. Copper cables ensure the reliable transmission of voice signals.

-

Television and Radio Broadcasting

Television and radio broadcasts are transmitted via communication lines using telecommunication cables. These cables ensure the reliable transmission of video and audio signals.

-

Mobile Communication

Mobile communication infrastructure operates through data transmission over telecommunication cables. These cables enable the transmission of data and voice signals between base stations.

-

Data Centers

Data centers are facilities where large amounts of data are stored and processed. Telecommunication cables facilitate data transmission between servers in data centers.

-

Industrial Applications

Telecommunication cables are also used in industrial applications such as industrial automation systems, security cameras, and smart city applications.

Telecommunication cables form the foundation of modern communication infrastructure and are widely used in various fields. They are indispensable for internet access, telephone services, television and radio broadcasting, mobile communication, data centers, and industrial applications. Our company aims to meet our customers' communication needs by offering a wide range of products tailored to telecommunication requirements.

``` Bu çevirinin size uygun olup olmadığını ve istediğiniz herhangi bir değişiklik olup olmadığını lütfen bana bildirin.

Go to Sector

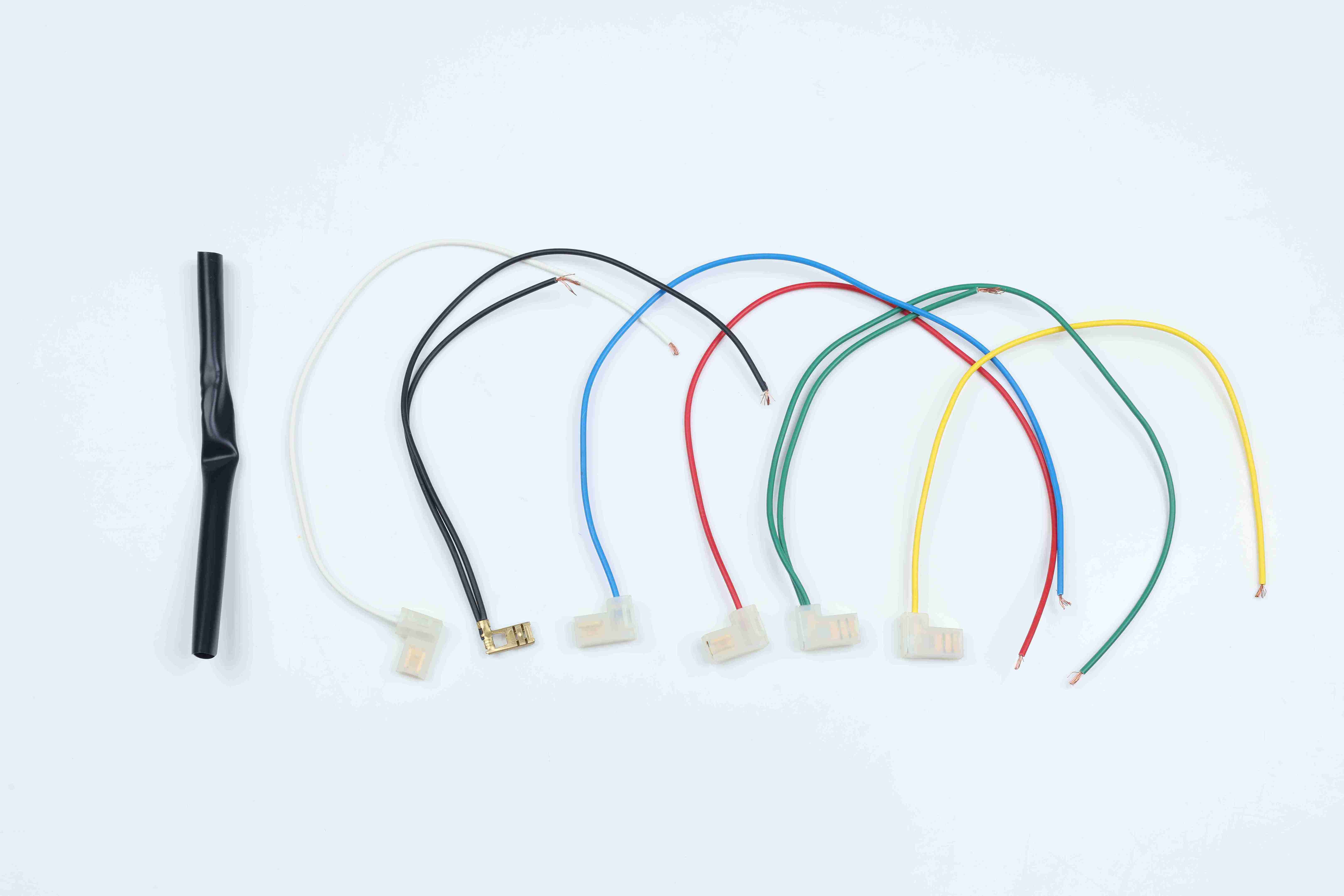

Vehicle Accessory Lamp Installations and Equipment Cables

Vehicle accessories are important components that enhance the visibility, functionality, and aesthetic value of vehicles. Many of these accessories require specially designed lamp installations and equipment cables to be properly installed. Here are the main types of vehicle accessory lamp installations and equipment cables:

- Headlamp Cables: The headlamp wiring system includes cables that control and provide power to the headlights located at the front of the vehicle. These cables may also include headlight height adjustment and headlight cleaning systems.

- Stop Lamp Cables: The stop lamp wiring system includes cables that control and provide power to the stop lamps located at the rear of the vehicle. These cables ensure that the stop lamps illuminate when the vehicle brakes.

- Fog Lamp Cables: The fog lamp wiring system includes cables that control and provide power to the fog lamps located at the front of the vehicle. Fog lamps provide additional illumination in low visibility conditions.

- Interior Lighting Cables: The interior lighting wiring system includes cables that control the ceiling lamps, reading lamps, and footwell lamps inside the vehicle. These cables are used to increase visibility and illuminate the interior space of the vehicle.

- Rearview Mirror Lamp Cables: The rearview mirror lamp wiring system includes cables that control the signal lamps located in the rearview mirror of the vehicle. These cables improve the visibility of the vehicle's driver and other drivers behind.

Vehicle accessory lamp installations and equipment cables are crucial for enhancing the functionality and safety of vehicles. Properly functioning headlamps, stop lamps, fog lamps, interior lighting lamps, and rearview mirror lamps require the use of appropriate cables and installations. Our company aims to meet our customers' needs by providing high-quality and reliable installations and cables for vehicle accessories.

Quality and Durability in Vehicle Lighting Equipment

Vehicle lighting equipment is critical for ensuring the safety of drivers and passengers and enhancing the visibility of vehicles. The quality and durability of this equipment are essential to provide long-lasting and reliable performance. Here are some important factors for ensuring quality and durability in vehicle lighting equipment:

- Use of High-Quality Materials: The quality and durability of vehicle lighting equipment depend on the quality of materials used. High-quality plastics, glasses, and metal alloys enhance the durability of the equipment and ensure long service life.

- Engineering Design and Testing: High-quality vehicle lighting equipment is carefully designed and subjected to comprehensive testing. The engineering design process is conducted meticulously to enhance the durability, performance, and reliability of the equipment. Additionally, testing the products under real-world conditions helps verify their reliability and durability.

- Strict Quality Control Processes: Manufacturers of high-quality vehicle lighting equipment implement strict quality control processes at every stage of production. These processes ensure that quality standards are met at every step, from material acquisition to production and assembly, and that the products are properly tested.

- Waterproofing and Dust Resistance: It is essential for vehicle lighting equipment to be resistant to external factors. Waterproofing and dust resistance features protect the equipment against external environmental conditions and provide long-lasting performance.

- Long-Lasting LED Technology: Vehicle lighting equipment produced using LED technology is more durable and long-lasting compared to traditional halogen lamps. LED technology consumes less energy and generates less heat, ensuring that the equipment operates smoothly for a longer period.

High-quality and durable vehicle lighting equipment is crucial for the safety of drivers and passengers. The use of high-quality materials, engineering design and testing, strict quality control processes, waterproofing and dust resistance features, and long-lasting LED technology are fundamental elements for ensuring the quality and durability of the equipment. Our company aims to provide our customers with reliable and long-lasting vehicle lighting equipment by adhering to these principles.

Materials Used in the Production of Quality Vehicle Accessory Lamp Installations

Vehicle accessories are important components that enhance the visibility, functionality, and aesthetic value of vehicles. Many of these accessories are produced using high-quality and durable materials. Here are the main materials used in the production of quality vehicle accessory lamp installations:

- High-Quality Plastics

Many parts used in vehicle accessory lamp installations are made from high-quality plastic materials. These plastics are specially selected for their impact resistance and long service life. Additionally, they are treated with UV-resistant coatings to preserve their color for a long time.

- Stainless Steel and Aluminum Alloys

Some accessories are made using stainless steel and aluminum alloys. These materials are known for their high strength and durability. Moreover, stainless steel and aluminum alloys provide resistance to external factors, ensuring long-lasting and reliable performance.

- Glass and Polycarbonate Materials

Glass and polycarbonate materials used in headlights and fog lights are known for their robust structures and high light transmittance properties. These materials are preferred for their resistance to external factors and their ability to maintain their optical performance for a long time.

- High-Performance Electrical Cables

Electrical cables used in vehicle accessory lamp installations must be high-performance and reliable. Flexibility, insulation properties, and conductivity are important factors that determine the quality of these cables. High-quality electrical cables provide a safe electrical connection and ensure proper operation of vehicle accessories.

The materials used in the production of quality vehicle accessory lamp installations are crucial for the durability, performance, and longevity of the products. High-quality plastics, stainless steel and aluminum alloys, glass and polycarbonate materials, and high-performance electrical cables are essential elements for ensuring the quality and reliability of these accessories. Our company aims to provide our customers with reliable and durable vehicle accessory lamp installations by using these high-quality materials.

Vehicle Accessory Lamp Installations and Driving Safety

Vehicle accessory lamp installations are critical components that contribute to the safety of drivers and the visibility of vehicles. Properly designed and installed installations can enhance driving safety in various ways:

- Enhances Visibility

Headlights, fog lights, stop lights, and other lighting equipment enhance the visibility of the vehicle. Especially in low-light conditions or poor weather conditions, properly functioning lamps make it easier for other drivers and pedestrians to see you.

- Improves Road Illumination

Headlights improve road illumination during night driving and allow the driver to see the road ahead more clearly. Driving without adequate lighting can pose potential hazards, but properly functioning headlights reduce this risk.

- Enhances Driving Comfort

Interior lighting lamps and other accessories can enhance driving comfort. Especially during night driving, interior lighting lamps allow passengers to move comfortably and perform necessary controls.

- Ensures Clarity of Indicators and Signals

Signal lamps and direction indicators allow the driver to communicate their intentions clearly to other drivers. Properly functioning signal lamps help other drivers anticipate turns or lane changes.

Go to Sector

The Importance of Headlamp Equipment in the White Goods Industry

White goods products play an important role in our daily lives and have become an indispensable part of modern life. The functionality and usability of these products depend on many factors, and headlamp equipment is one of these factors. Here are some reasons why headlamp equipment is important in the white goods industry:

- Lighting and Visibility: Headlamp equipment provides better visibility by illuminating the interior or exterior of white goods products. Headlamps in products such as refrigerators, washing machines, and dishwashers allow users to see the contents of the products more easily.

- Ease of Use: A proper lighting arrangement makes the use of white goods products easier and more efficient. Headlamp equipment helps users see the buttons, control panels, or items inside the product more clearly, thus providing more convenience during product use.

- Safety: Headlamp equipment enhances the safety of white goods products. Especially in products like ovens, stoves, and other heating devices, proper lighting helps users see the cooking status of food better, thereby helping them be more careful about food burning or undercooking.

- Aesthetic Value: Headlamp equipment contributes to the design aesthetics of white goods products. Modern and stylish headlamps enhance the exterior design of the product and provide users with an attractive appearance.

The importance of headlamp equipment in the white goods industry is significant. Factors such as lighting, visibility, ease of use, safety, and aesthetic value come together with the use of the right headlamp equipment, allowing users to make the most of white goods products. Therefore, selecting and using the correct headlamp equipment is extremely important for white goods manufacturers.

Features of Specialized Cables Designed for Headlamp Installation and Equipment in the White Goods Sector

Specialized cables designed for headlamp installation and equipment used in white goods products have specific characteristics in terms of reliability, durability, and performance. These cables not only ensure the longevity of products but also support their safe and efficient operation. Here are some important features of these specially designed cables:

- High Temperature Resistance: Cables used for headlamp installation and equipment in white goods products should be resistant to high temperatures. These cables can be safely used in products operating at high temperatures, such as ovens, stoves, or other heating devices.

- Flexibility and Compatibility: Specialized cables should be flexible enough to easily adapt to the complex structures of headlamp installation and equipment. This flexibility provides convenience during product assembly and use.

- Fire Resistance: Another critical feature for safety is fire resistance. Cables designed for headlamp installation and equipment in white goods products should have high fire resistance characteristics, ensuring the safe use of products.

- Longevity and Durability: Specialized cables should be durable to provide long-term and reliable performance. Even when subjected to frequent bending, flexing, or other mechanical stresses, these cables should not lose their functionality.

- Insulation and Isolation: The insulation and isolation characteristics of cables used in headlamp installation and equipment are also crucial. These features enhance electrical safety and protect cables from external factors.

Specialized cables designed for headlamp installation and equipment in the white goods sector are an important component that enhances the reliability, durability, and performance of products. Features such as high temperature resistance, flexibility, fire resistance, longevity, and insulation make these cables safe and efficient to use. Therefore, selecting the right cable is of great importance for white goods manufacturers.

Compliance with Quality Standards in Headlamp Equipment Production for White Goods

Ensuring compliance with quality standards in the production of headlamp equipment for white goods is critically important for the safety, durability, and performance of products. Our company, while manufacturing high-quality headlamp equipment, strictly adheres to recognized quality standards in the industry.

- Compliance with International Standards: Compliance with internationally recognized standards is of great importance in the production of headlamp equipment. Our company manufactures products in full compliance with the standards set by international standard organizations. These standards determine the quality, safety, and performance of products.

- Strict Quality Control Processes: Strict quality control processes are implemented to manufacture high-quality headlamp equipment. Quality control is conducted at every stage of the production process, and products are meticulously inspected to ensure compliance with specified quality standards.

- Use of High-Quality Materials: The quality of headlamp equipment is directly related to the quality of materials used. Our company ensures the longevity and reliable performance of products by using high-quality and durable materials in production.

- Continuous Improvement and Innovation: Continuous improvement and innovation processes are important to ensure compliance with quality standards. Our company regularly reviews production processes and identifies opportunities for improvement. Additionally, we continuously innovate to enhance the quality and performance of products by following new technologies.

- Customer Feedback Importance: Giving importance to customer feedback is essential to ensure customer satisfaction and improve product quality. Our company carefully reviews feedback from our customers and evaluates these feedback to continuously improve our products.

Ensuring compliance with quality standards in the production of headlamp equipment for white goods is one of our priorities. Compliance with international standards, strict quality control processes, use of high-quality materials, continuous improvement, and giving importance to customer feedback are fundamental elements to ensure the quality and reliability of our products. Thus, we aim to provide our customers with high-quality and reliable headlamp equipment.

Go to Sector

Tabii ki, aşağıda metnin İngilizceye çevrilmiş hali HTML biçiminde: ```html

Specialized Fog Lamp Installations and Equipment for the Defense Industry

In the defense industry, especially in military air bases and operational areas, fog lamp installations and equipment have critical importance in increasing visibility and ensuring security. These specially designed systems have specific features to operate effectively even in harsh weather conditions.

Features

- High Reliability and Durability: Fog lamp installations and equipment designed for the defense industry adhere to high reliability and durability standards. These systems are designed and manufactured to operate seamlessly and reliably in military operations.

- Visibility Enhancement: Fog lamp installations are designed to enhance visibility even in dense fog or poor weather conditions. Specially positioned lamps and lighting systems enable pilots and personnel to continue operations.

- Easy Installation and Maintenance: Fog lamp installations designed for the defense industry are designed to require easy installation and maintenance. These systems can be quickly mounted and have easily accessible parts for maintenance when needed.

- Low Visibility: Fog lamp installations have low visibility characteristics. These systems are designed to limit the detection and targeting capabilities of enemy observers or aircraft.

- Longevity and Performance: Fog lamp installations and equipment designed for the defense industry are tested to provide longevity and high performance. These systems are manufactured to withstand harsh conditions and are designed for long-term use.

- Integration Capability: Fog lamp installations are designed to be integrated with other components of defense systems. This integration capability enables the effective operation of comprehensive defense systems.

Specialized fog lamp installations and equipment for the defense industry play a critical role in increasing visibility and ensuring security in military operations. Features such as high reliability, durability, low visibility, easy installation and maintenance, longevity, and performance enable these systems to be preferred in the defense industry. Defense industry companies can enhance operational efficiency and ensure the safety of military personnel by using these specialized fog lamp installations and equipment.

The Impact of Fog Lamps on Aviation Safety and Operations

In the aviation industry, fog lamps play a critical role in ensuring the safe takeoff and landing of aircraft in dense fog, foggy weather, or low visibility conditions. These special lamps enhance aviation safety while supporting operational efficiency.

Visibility Enhancement

Fog lamps provide better visibility for pilots by illuminating runways, taxiways, and airport infrastructure in dense fog or low visibility conditions. This allows pilots to safely navigate the aircraft and make a safe landing at the airport.

Safe Takeoffs and Landings

In dense fog or low visibility conditions, fog lamps enable pilots to better see the runway and landing taxiway, allowing for safe takeoffs and landings. This ensures the regularity and safety of airport operations.

Operational Efficiency

Fog lamps ensure the continuity of aviation operations and minimize flight delays. Even in dense fog or low visibility conditions, fog lamps enable aircraft to safely take off and land, thereby enhancing operational efficiency.

Assistance in Emergency Situations

Fog lamps can also assist in emergency situations. In dense fog or low visibility conditions, fog lamps can help rescue teams and emergency personnel better see the runway and airport infrastructure.

Aviation Safety and Regulations

Aviation safety standards regulate the use and placement of fog lamps at aviation facilities. These standards provide guidelines to airport operators and airlines for the proper placement and maintenance of fog lamps.

Fog lamps are an important component that enhances safety and supports operational efficiency in the aviation industry. In dense fog or low visibility conditions, fog lamps provide pilots and airport personnel with better visibility for safe takeoffs and landings, thereby increasing aviation safety and maximizing operational efficiency.

Fog Lamp Solutions for the Aviation Sector

Your company is a leading provider of fog lamp solutions in the aviation industry. We offer advanced technology-based solutions to ensure safe takeoffs and landings in dense fog and low visibility conditions.

Fog Lamp Products

- Runway Fog Lamps: Special design fog lamps placed on the edges of runways to provide better visibility for aircraft during takeoff and landing.

- Taxiway Fog Lamps: Fog lamps used to illuminate taxiways in low visibility conditions to ensure the safe movement of aircraft.

- Airport Perimeter Fog Lamps: Fog lamps that illuminate roads, parking areas, and other infrastructure around the airport, helping pilots find their way more easily.

Technological Innovation

Our company focuses on enhancing aviation safety by using state-of-the-art technology in fog lamp solutions. Our fog lamps are manufactured using LED technology, providing low energy consumption, long life, and high performance.

Customized Solutions

We offer customized fog lamp solutions tailored to the needs of our customers. We provide specially designed fog lamps based on the characteristics of airports, runway and taxiway geometry, and operational requirements.

Quality and Reliability

Our company places great importance on reliability and quality standards in the aviation industry. Our products are rigorously tested and certified to ensure full compliance with international aviation regulations and standards.

Customer Support and Maintenance Services

With a focus on customer satisfaction, we offer comprehensive support and maintenance services to customers using our fog lamp solutions. Our professional technical support team is always ready to assist customers with installation, setup, and maintenance processes.

Contact

Contact us for safe and efficient fog lamp solutions in the aviation sector. Our expert team will be happy to collaborate with you to provide customized solutions tailored to your needs.

Fog Lamp Standards Used in the Aviation Sector

Fog lamps used in the aviation sector are subject to strict standards set by international aviation authorities. These standards are established to ensure the reliability, durability, and performance of fog lamps.

FAA (Federal Aviation Administration) Standards

The FAA regulates and oversees aviation activities in the United States. The FAA establishes specific standards for fog lamps used in aviation facilities. These standards cover requirements for the design, assembly, installation, and maintenance of fog lamps.

EASA (European Aviation Safety Agency) Standards

EASA is responsible for regulating aviation safety and regulations in Europe. EASA sets standards for the use of fog lamps in aviation facilities across Europe. These standards include requirements for safety, performance, and environmental compliance of fog lamps.

ICAO (International Civil Aviation Organization) Standards

ICAO is the primary authority for setting international aviation standards. ICAO develops internationally recognized standards for fog lamps used in aviation facilities. These standards establish requirements that must be adhered to in aviation operations in all countries.

ISO (International Organization for Standardization) Standards

ISO is an international organization that develops standards to set international standards. ISO develops general standards for equipment used in the aviation sector. Fog lamps used at aviation facilities must comply with the quality and performance standards set by ISO.

Fog lamps used in the aviation sector are subject to strict standards set by international authorities such as FAA, EASA, ICAO, and ISO. These standards are designed to ensure the safety, performance, and environmental compliance of fog lamps. Full compliance of fog lamps used in aviation facilities with these standards supports safe and efficient aviation operations.

```

Go to Sector

The Importance and Usage Areas of Lighting Systems in the Aviation Industry

The aviation industry is a sector where technological advancements and innovations frequently occur. As a result of these developments, safety, comfort, and performance standards in aviation are constantly rising. In this context, lighting systems also play a crucial role in the aviation industry.

Importance of Lighting Systems

- Safety: Lighting systems that function correctly and effectively during aircraft takeoff and landing, night flights, and adverse weather conditions help prevent accidents.

- Navigation: Lighting systems for aircraft play a critical role in determining the positions of runways and other aircraft.

- Emergency Situations: Lighting systems assist in determining the aircraft's position and preventing collisions during emergency situations.

- Air Traffic Control: Lighting systems help air traffic controllers determine and guide aircraft positions.

Usage Areas

- Aircraft Body Lights: Lights located on the aircraft body generally assist in illuminating the runway during takeoff and landing and making the aircraft visible to other aircraft.

- Tail Lights: Tail lights, located at the rear of aircraft, are used to indicate the aircraft's position to other aircraft.

- Wingtip Lights: Wingtip lights, mounted on the tips of aircraft wings, enhance the aircraft's visibility from the side.

- Navigation Lights: Navigation lights are used during nighttime flights to assist in determining the aircraft's direction.

- Emergency Lights: Emergency lights help determine the aircraft's position during emergency situations and attract attention by signaling to other aircraft.

In the aviation industry, lighting systems are indispensable for safe and efficient flights. These systems are crucial for ensuring the safe takeoff and landing of aircraft, facilitating navigation, and determining aircraft positions during emergencies. Aviation companies and manufacturers continually engage in research and development efforts to enhance the quality and reliability of these systems, making the aviation industry safer and more efficient.

Cable Standards Used in Aviation Signal Lamp Installations

In the aviation industry, cables used in aircraft signal lamp installations must adhere to specific safety and durability standards. These standards are established to ensure the safety of aircraft and the proper and reliable operation of signal lamps.

Special Safety Standards

- FAA (Federal Aviation Administration) Standards: The FAA establishes safety standards for organizations operating in the aviation industry in the United States. Cables used in aviation signal lamp installations must meet the FAA's specified electrical safety requirements.

- EASA (European Aviation Safety Agency) Standards: In Europe, EASA sets safety standards for organizations operating in the aviation industry. EASA standards encompass materials used in cables as well as assembly and testing requirements.

- RTCA (Radio Technical Commission for Aeronautics) Standards: RTCA is an organization that develops technical recommendations and standards for electrical and electronic equipment in the aviation industry. Standards established by RTCA for cable design and testing are recognized authorities in terms of safety and compliance.

Durability Standards

- High-Temperature Resistance: Cables used in aviation signal lamp installations must be resistant to high temperatures. Considering they may be located near aircraft engines and other equipment, cables need to withstand heat.

- Vibration and Impact Resistance: Aircraft are frequently exposed to vibrations and impacts during flight. Therefore, cables used in signal lamp installations must be resistant to vibrations and impacts and have secure connections.

- Water and Corrosion Resistance: In the aviation environment, water and corrosion can adversely affect cable performance. Therefore, cables used in signal lamp installations must be resistant to water and corrosion.

Ensuring that cables used in aviation signal lamp installations comply with specific safety and durability standards is critical for aircraft safety and operational performance. These standards are established to meet the safety and quality requirements of the aviation industry. Aviation companies and manufacturers continue to select cables that comply with these standards to support safe and efficient flights.

Sectors Dealing with Aviation Signal Lamp Installations and Equipment

1. Airlines

Airlines prioritize signal lamp installations and equipment for the safe and regular takeoff and landing of aircraft. This equipment facilitates the guidance of aircraft to runways and provides necessary information to ground service teams.

2. Airport Operators

Airport operators require signal lamp installations and equipment to manage and regulate airport operations. This equipment ensures the safe movement of aircraft on taxiways and regulates transitions between runways.

3. Air Traffic Control Units

Air traffic control units are responsible for directing and monitoring air traffic at airports and in airspace. Signal lamp installations and equipment provide important reference points for air traffic controllers to determine aircraft positions and statuses.

4. Aviation Technology Companies

Aviation technology companies develop innovative solutions related to signal lamp installations and equipment and are involved in the design and manufacturing of this equipment. These companies work in technology and engineering fields to meet the safety and efficiency requirements of the aviation industry.

5. Aviation Training Institutions

Aviation training institutions provide training for aviation professionals such as pilots, air traffic controllers, and airport personnel. These institutions offer training on how to use and manage signal lamp installations and equipment effectively.

6. Aviation Industry Suppliers

Aviation industry suppliers provide various products and services, including signal lamp installations and equipment, to aviation companies and airport operators. These suppliers work to meet the needs of the aviation industry with quality and reliable equipment.

Providing Reliable and Durable Cable Materials in the Aviation Industry

The cable materials used in the aviation industry are crucial for the safety and operational efficiency of aircraft. Therefore, the reliability and durability of these cable materials must be ensured. Quality material selection is the first step. High-quality and reliable materials should be preferred, often manufactured from special alloys, thermoplastics, or thermosets. Robust and durable materials ensure that cables withstand the demanding aviation environment for extended periods.

It is also critical that the cable materials used adhere to standards established by the aviation industry. Organizations such as the FAA (Federal Aviation Administration) and EASA (European Aviation Safety Agency) set specific standards for aviation materials. These standards define material properties, fire resistance, electrical characteristics, and other performance criteria.

Strict quality control should be applied throughout the production process. Manufacturers should carefully monitor each stage of material production to ensure compliance with quality standards. Material samples are tested to evaluate durability, temperature resistance, electrical properties, and other performance criteria.

Continuous research into innovative technology and engineering solutions is necessary to ensure the provision of reliable and durable cable materials in the aviation industry. New material compositions, production techniques, and coating methods can enhance cable performance and longevity. Lastly, cable materials should be continuously improved and tested. Manufacturers should continually enhance their materials based on feedback and make them more reliable. The reliability and durability of new products and technologies should be verified through testing. These steps contribute to ensuring the provision of reliable and durable cable materials in the aviation industry.

Go to Sector

Why Do We Use It?

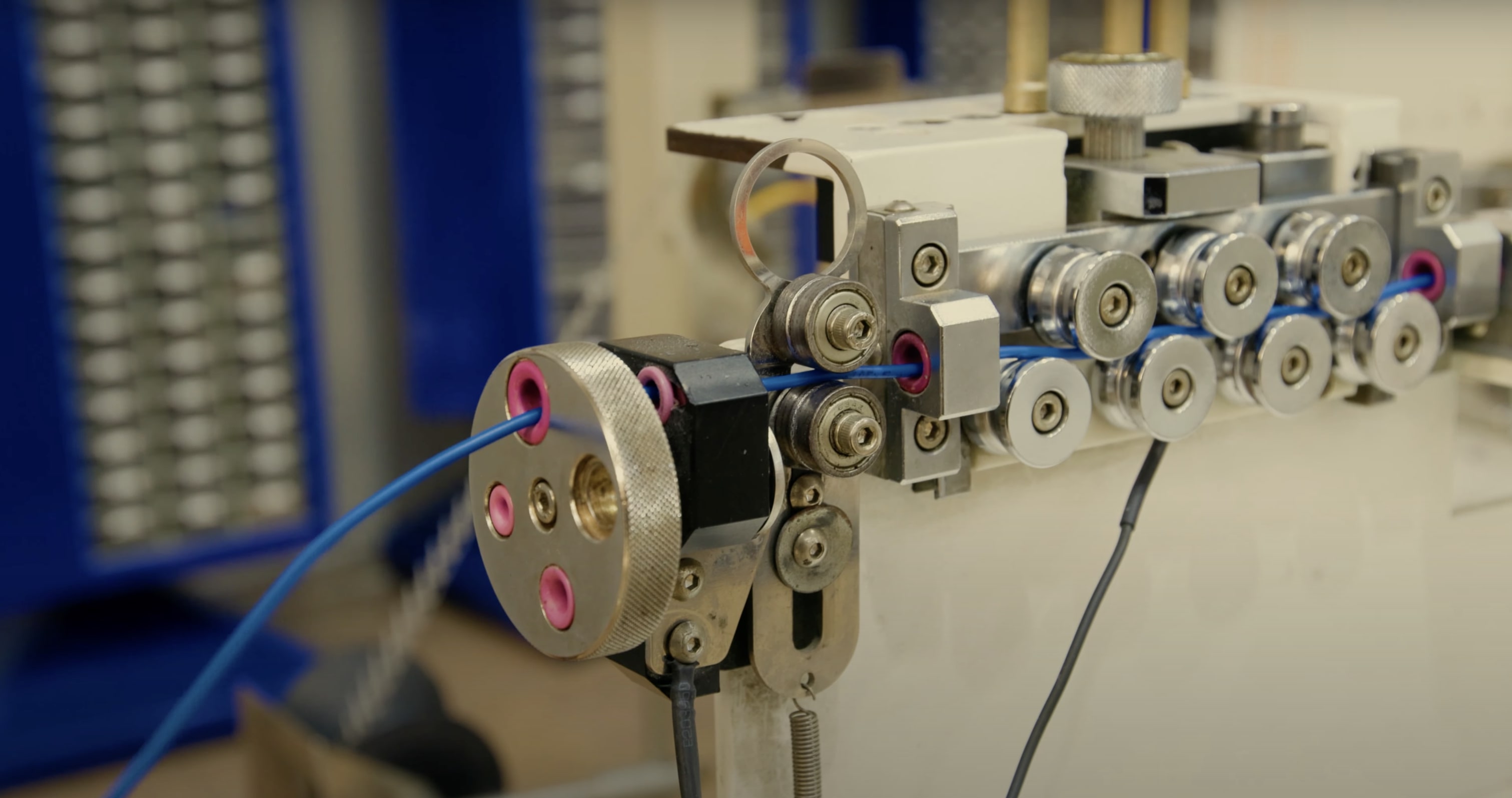

The Role and Characteristics of Cables in the Automotive Industry

The automotive industry is a constantly evolving and changing sector. As the complexity and functionality of vehicles increase, the quality and performance of the components used inside them become important. One of these components is the cables themselves. Cables are one of the fundamental elements that make up a vehicle's electrical system and perform many critical functions.

The Role of Cables

- Power Distribution: Cables are used to transmit energy within the vehicle and provide power to different systems. Many components such as engine starting, headlights, and air conditioning receive power through cables.

- Data Transmission: Modern vehicles collect and process data continuously through various sensors and control units. Cables play a critical role in transmitting this data.

- Transmission Control: Cables are used to control and manage automotive systems. Components such as the braking system or gear shifting mechanism are controlled through cables.

- Safety and Comfort: Cables ensure the operation of safety systems within the vehicle. Safety components like airbags and parking sensors, as well as comfort systems like air conditioning and power windows, operate through cables.

Cable Characteristics

- Durability: The automotive environment can be subjected to harsh conditions. Cables need to be durable and resistant to vibrations, impacts, abrasion, and temperature changes.

- Insulation: Proper insulation of electrical cables is crucial. Correct insulation reduces the risk of short circuits and ensures safety. Additionally, insulation material protects cables from external factors.

- Flexibility: Flexible cables facilitate ease of installation and movement within the vehicle during assembly and operation. This allows cables to be routed and installed more efficiently.

- Heat Resistance: Automotive systems are often exposed to high temperatures. Cables need to be heat-resistant to maintain their performance.

- Electromagnetic Compatibility (EMC): Modern vehicles contain numerous electronic systems that need to be compatible with each other. Meeting EMC requirements helps prevent electromagnetic interference.

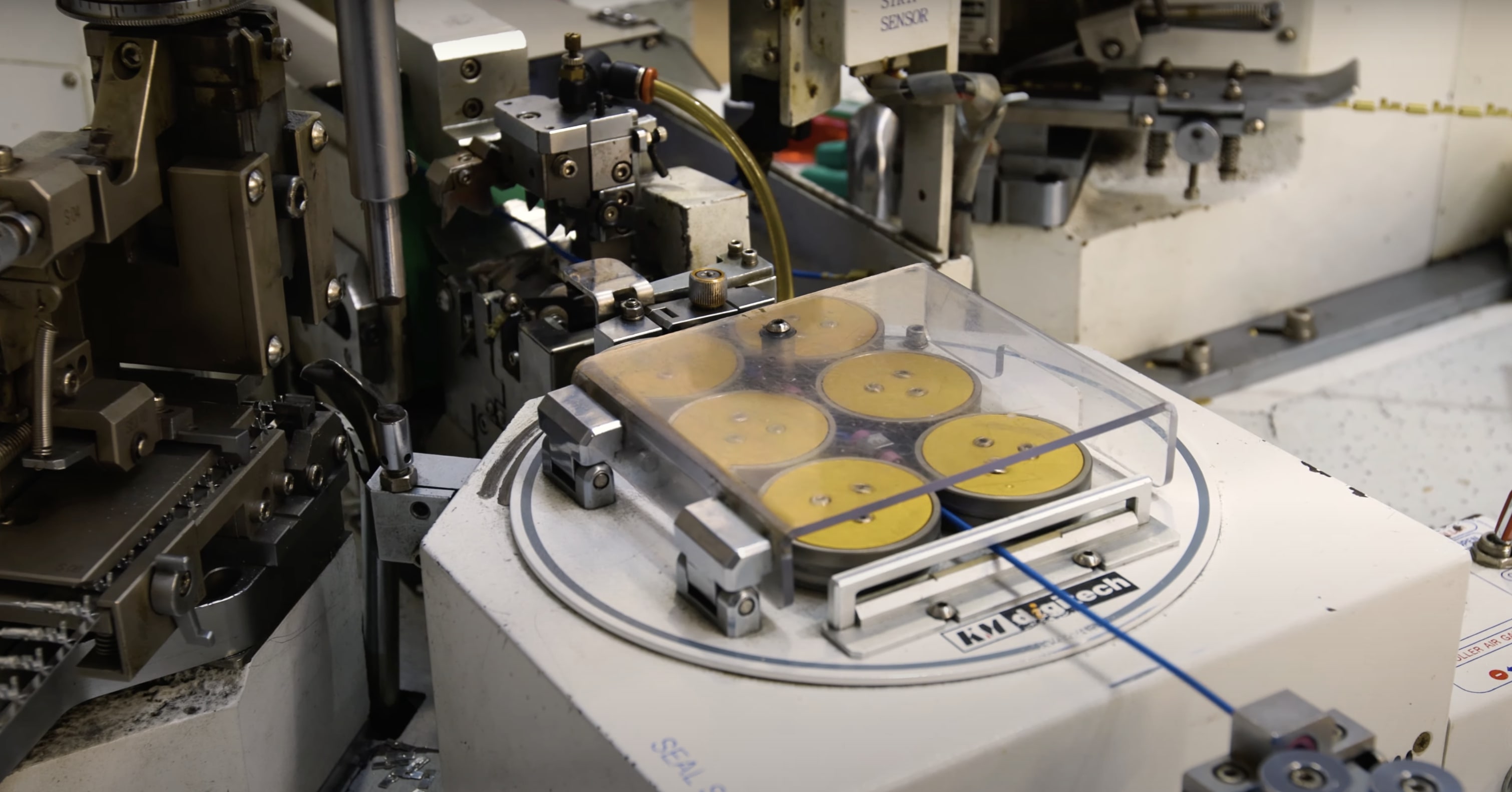

Quality Standards and Safety Measures for Cables Used in Automotive Lighting Systems

Automotive lighting systems are of vital importance for drivers to safely navigate during night-time and adverse weather conditions. The reliable operation of these systems is critical for the safety of drivers and other road users. Ensuring the reliability of automotive lighting systems involves adhering to quality standards and implementing safety measures for the cables used.

Cable Quality Standards

- UL (Underwriters Laboratories) Standards: Cables used in the automotive industry should generally comply with UL standards. UL conducts various tests and evaluations to determine the safety and performance of cables. These standards include specific requirements for insulation material, conductor material, and other properties of cables.

- ISO 6722: ISO 6722 standards for automotive cables define their electrical and mechanical properties. These standards provide detailed information about the durability, conductivity resistance, insulation quality, and other technical properties of cables.

- SAE J1128: SAE J1128 standards established by the Society of Automotive Engineers cover general requirements for automotive cables. These standards include topics such as the electrical properties of cables, resistance to environmental conditions, and ease of installation.

Go to Sector